Sensor torch height control Hypertherm

Specifically designed to integrate with Hypertherm’s CNC solutions, the Sensor® torch height control (THC) is a full-featured torch height control system that can significantly increase the productivity and profitability of your shape cutting operation.

The easy-to-use, easy-to-install unit offers integrated CNC software features and closed loop servo control, as well as the latest advances in system integration and hardware reliability.

- Benefits

- Simple, reliable operation

- High-performance features

- Higher productivity

- Lower operating costs

- Improved cut quality and consumable life

- Specifications

- Resources

Benefits

Sensor THC is a torch height control system which is integrated to the CNC incorporating Hypertherm cutting process expertise at the touch of a button. Built in cut charts provide all parameters to the plasma system and THC reducing job setup time and operator errors while increasing productivity.

- With Sensor THC, performance advantages are achievable without operator input, eliminating the need for extensive training and allowing you to get the best performance across any shift with any operator at any location.

- The operational logic is located inside the CNC providing one simple location for the complete job setup

- Use of Hypertherm’s embedded process expertise through built in cut charts or part program process codes

- Sensor THC supports the use of custom lifters for custom performance and allowing support for unique applications such as plasma bevel, tube and pipe and waterjet

- Remote Diagnostics via the internet through the Remote Help on the CNC

- Enables SureCut Technology features such as TrueHole® , TrueBevel™ and Rapid Part™

Simple, reliable operation

- Complete built-in test for easy hook-up, system test, and configuration

- Built in user-programmable process control parameters for initial height sense, plasma arc volts, torch height Disable, automatic kerf crossing detection, skip IHS, and IHS offset

- Automatic retry on arc transfer error

High-performance features

- Arc voltage range 50-300 VDC in 0.5 volt increments

- Initial height sense can be done with ohmic contact or position error stall detection

- Manual or full automatic height control

- Auto Arc Voltage Set

- Automatic preflow during IHS

- Support for arc style marking torches

- Complete servo loop adjustments, including proportional, integral, derivative, and feed-forward gains

Higher productivity

- Rapid Part™ technology minimizes cut-to-cut cycle time – for a dramatic increase in parts per hour

- Automated Initial Height Sense (IHS) minimizes the time for the torch to find the plate without risking damage; IHS is automatically skipped where possible based on part geometry and plate characteristics

Lower operating costs

- Optimal consumable life and superior cut quality through arc voltage sampling and control

- Extremely robust mechanics ensure highest reliability

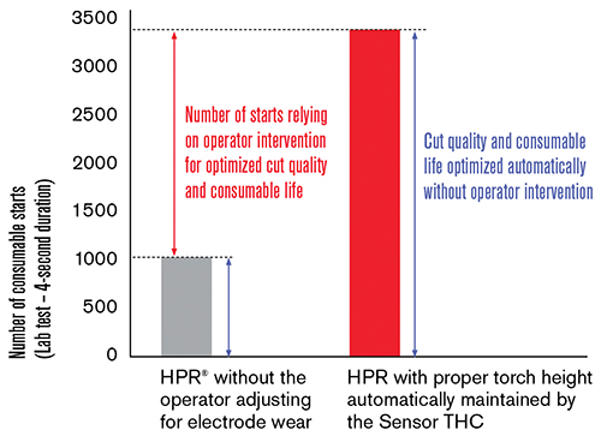

Number of consumable starts with < 0,25 mm (0.010″) deviation from proper cut height without operator intervention (130 A) 12 mm (1/2″) mild steel (see chart)

Improved cut quality and consumable life

- Traditional torch height controls require operators to periodically adjust arc voltage to ensure proper cut height. Using Hypertherm’s proprietary techniques, the Sensor THC continuously samples arc voltage and automatically adjusts arc voltage for proper torch height over the life of the consumables without requiring operator input.

- Optimal consumable life and superior cut quality are achieved through automatic arc voltage sampling and position control.

Specifications

| Dimensions | 127 mm (5.0″) X 152 mm (5.9″) X 526.5 mm (20.73″) |

|---|---|

| Lifter stroke length | 241 mm (9.4″) |

| Weight | 11.27 kg (24.85 lb) without breakaway and torch block |

| Motor | OEM Supplied – 60 mm (2.36 in.) flange with a 70 mm (2.756 in.) bolt circle diameter |

| Maximum lift capacity rating | 11.4 kg (25 lbs) |

| Maximum speed rating | 15,200 mm/min (600 in/min) |

| Communication protocol | Discrete wiring to motor and I/O EtherCat to the HPR plasma system |

| Humidity | 95% RH |

| Operating environment | -10° C to + 40° C ambient (14° F to 104° F ambient) |

| Optional torch mount / breakaway assembly | 11.4 kg (25 lbs) magnetic (recommended) 4.5 kg (10 lbs) magnetic Torch mounting block options include 51 mm (2″), 44 mm (1-3/4″) and 35 mm (1-3/8″) |

| Alignment laser pointer | Included as standard |

| Table types | Downdraft and water table |