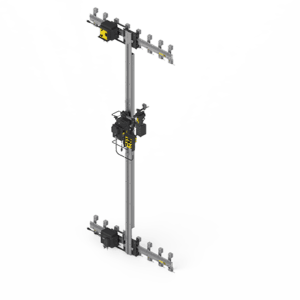

DC IV – MAX BUG-O

The Turnkey Solution for Off-Table, Repeatable Beveling and Cutting

For metal workers who need to easily and repeatably bevel or vertically cut metal, the DC-IV MAX is a unique turnkey solution that combines a purpose built tractor and controller from Bug-O Systems with a Powermax® series or MAXPRO® plasma cutting system from Hypertherm®.

- Benefits

- Features

Benefits

As with all Bug-O equipment, you can expect the following advantages:

Increase Productivity – Tool-less setup reduces machine down time, increases operator efficiency, and eliminates lost time due to complicated setups. Bevel and rail alignments offer fast, repeatable setup for both speed and precision.

Reduce Material Handling – Lightweight, compact footprint allows for the machine to be brought to the workpiece both inside the shop and out in the field.

Improve Quality – Precision speed control along with the rigid aluminum track-based system, provides smooth torch motion at optimal travel speeds for high quality plasma cuts. With travel speeds of 0-100 inches per minute (0-254 cm/min) the DC-IV Max has the operating range needed for plasma cutting and gouging with the Powermax® and MAXPRO® plasma systems.

Reduce Distortion and Cut Edge Prep – As compared to oxy fuel cutting the higher torch travel speeds for plasma cutting reduces the risk of metal distortion. Utilizing the supplied Hypertherm® cut charts for optimal setup and operation will increase operator productivity reducing the rework, grinding, and cleanup required after the cut has been made.

Why does mechanized table cutting become a barrier in the value stream for fabricators?

Features

- ONETOUCH® – One button start for both tractor and plasma system.

- Integrated start delay to allow arc transfer before tractor motion

- PSC®, Process Stop Control – When the cut is done, the entire process stops automatically.

- Integrated with Hypertherm® Powermax® series and MAXPRO® power sources

- Vertical and bevel cut charts are provided for Powermax® and MAXPRO®

- Torch alignment guide for bevel cutting setup

- Heavy duty racking provides smooth and stable operation

- Independent manual bevel and lead/lag angle controls

- Built-in degree dial on bevel and lead/lag angle

- Torch breakaway with auto process stop

- Auto shutdown at end of plate

- Pierce timer settable directly in seconds

- Oxy fuel accessory is available for cutting >2″ (50.8 mm)

- Display shows tractor speed in inches/min or cm/min

- Emergency stop

- Tool-less setup

- Fine speed adjustment

- To accommodate the high frequency starting process of the MAXPRO200®, the MAXPRO200® bundle features hardened electronics with enhanced grounding to ensure reliable use.

- Made in USA