ArcGlide torch height control Hypertherm

Traditional torch height controls require operators to periodically adjust arc voltage to ensure proper cut height. Using Hypertherm’s proprietary techniques, the ArcGlide® torch height control (THC) continuously samples arc voltage and automatically adjusts arc voltage for proper torch height over the life of the consumables without requiring operator input.

The result: optimal cut quality, improved productivity and reduced operating costs for plasma cutting applications – including True Hole® capability for HyPerformance® plasma HPRXD® installations. The ArcGlide THC is available in both CNC-integrated (with Hypernet® communication) and standalone configurations.

- Benefits

- Lower operating costs

- Specifications

- Resources

Benefits

Higher productivity

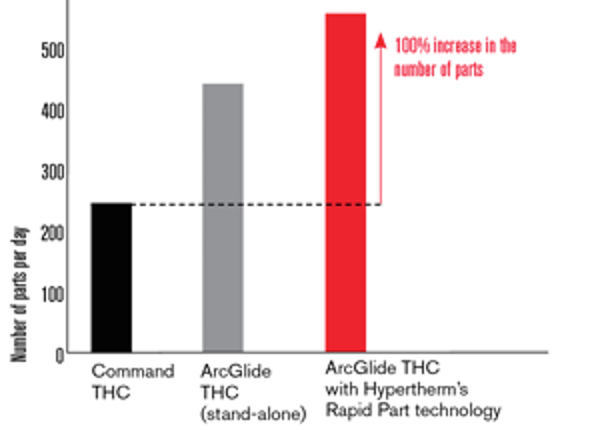

- Rapid Part™ technology minimizes cut-to-cut cycle time – for a dramatic increase in parts per hour

- Automated Initial Height Sense (IHS) minimizes the time for the torch to find the plate without risking damage; IHS is automatically skipped where possible based on part geometry and plate characteristics

- Rapid z-axis movement to an automatically set retract height minimizes torch retract time

Number of parts – 203 mm flange (8″) (see chart)

Lower operating costs

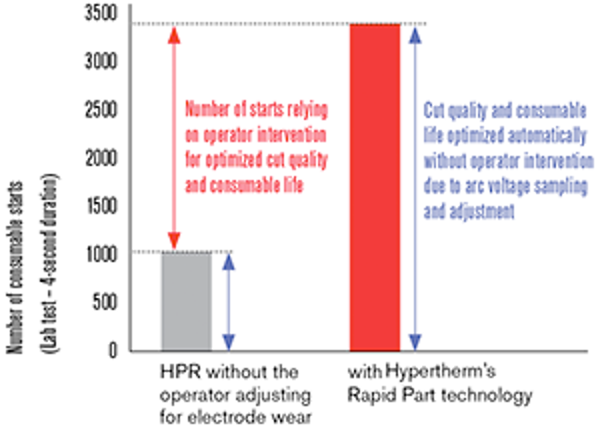

- Optimal consumable life and superior cut quality through arc voltage sampling and control

- Extremely robust mechanics ensure highest reliability, backed by a two-year warranty

- Hypernet® installation simplifies operation and reduces installation time

Number of consumable starts with < 0.25 mm (0.010″) deviation from proper cut height without operator intervention (130 A) 12 mm (1/2″) mild steel (see chart)

Specifications

| Regulatory | CE, CSA, GOST-R |

| Temperature range | -10° C to + 40° C ambient (14° F to 104° F ambient) |

| Humidity | 95% RH |

| Dimensions | Lifter: 127 mm (5.0″) X 151 mm (5.9″) X 743 mm (29.3″) HMI: 298 mm (11.7″) X 131mm (5.1″) X 118 mm (4.6″) Control module: 359 mm (14.1″) X 157 mm (6.2″) X 206 mm (8.1″) |

| Torch mount / breakaway assembly | 11.4 kg (25 lbs) magnetic (recommended) 4.5 kg (10 lbs) magnetic Pneumatic Torch mount options include 51 mm (2″), 44 mm (1-3/4″) and 35 mm (1-3/8″) |

| Stroke speed | 15240 mm/min (600 ipm) |

| Lift capacity | 11.4 kg (25 lbs) |

| Warranty | Two-year warranty standard |

| Communication protocol | Hypernet® to CNC Discrete wiring or Hypernet to the plasma system |

| Voltage | 115V/230V for the HMI at 50/60hz 115V/230V for the control module at 50/60hz |

| Lifter stroke length | 241 mm (9.4″) |

| Table types | Downdraft and water table High amperage capacity 1 – 4 plasma system |

| Communication protocol | w/ Hypernet – Hypernet to the CNC/HMI with Hypernet or discrete to the plasma w/o Hypernet – Hypernet to the HMI or RS-422 serial to the CNC with discrete to the plasma |