LF3015LNR METAL TUBE AND PLATE LASER CUTTING MACHINE

LF3015LNR METAL TUBE AND PLATE LASER CUTTING MACHINE

Autofocus Laser Cutting Head

Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Dual Use and Cost-saving

G.WEIKE GR series fiber laser cutting machine can not only cut metal plates,but also metal pipes. It has many uses and can save the space of more than 50%,which effectively improve productivity.

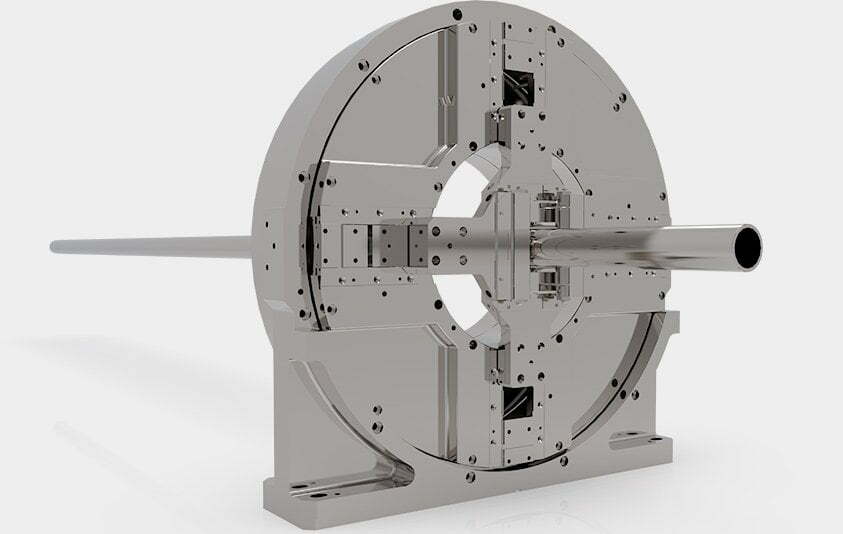

Clamp Design

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-300mm.

The Segmented Rectangular Tube Welded Bed

The internal structure of the bed adopts the aircraft metal honeycomb structure,which is welded by a number of rectangular tubes. Stiffeners are arranged insidethe tubes to increase the strength and tensile strength of the bed, it also increasesthe resistance and stability of the guide rail so as to effectively avoid thedeformation of the bed. High strength, stability, tensile strength, ensuring 20 years of use without distortion; Thickness of rectangular pipe wall is 10mm,and weights 4500 kg.

3rd Generation Aviation Aluminum Beam

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Machine Advantage

Stainless Steel Protection Design

The operating area adopts a 304 stainless steel design to prevent high temperature cutting sparks from damaging the machine’s surface.

IPAD Designing Screen

Use the high definition toughened glass screen, more exquisite and delicate, the operation is smoother.

Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

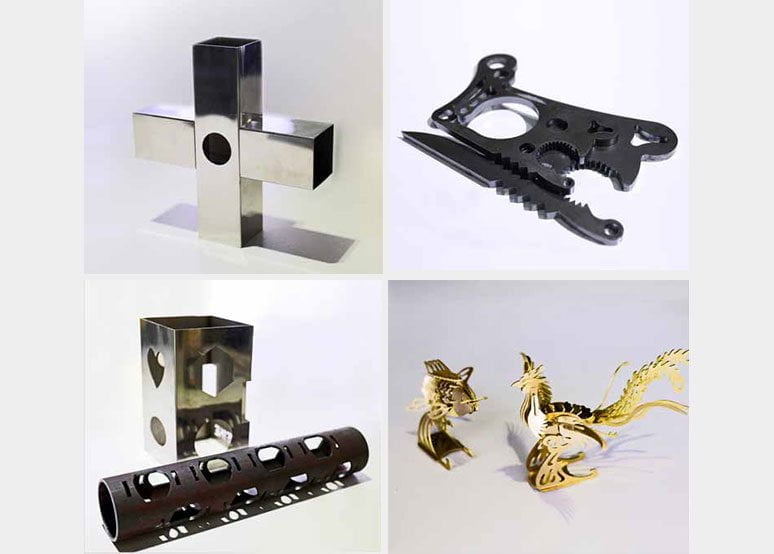

Industry Applications

Since sheet and pipe integrated design, Industry adaptability of LF3015LNR has been greatly enhanced, including petroleum and pipe material, fitness equipment and other pipe material mainly mechanical processing, automotive manufacturing, machine cabinet and other board materials mainly mechanical processing, etc. Specially used for cutting 0.5-5mm carbon steel sheets (pipes), 0.5-2.5mm stainless steel sheets, galvanized steel(pipes), electrolytic zinc-coated steel sheet(pipes), silicon steel(pipes) and other kinds of thin metal sheets and pipes. Range of pipe diameters: 20-220mm.

Technical Parameters

| Machine Model | LF3015LNR |

| laser power | 1000W 2000W 3000W(Optional) |

| Dimensions | 5315*3930*1950mm |

| working area | 3000mm x 1500mm |

| Repeat positioning accuracy | ±0.02mm |

| Max speed | 80m/min |

| Max acceleration | 1.0G |

| Voltage and frequency | 380V/50Hz/60Hz/60A |