© 2021, Anateco.

All right reserved.

In stock

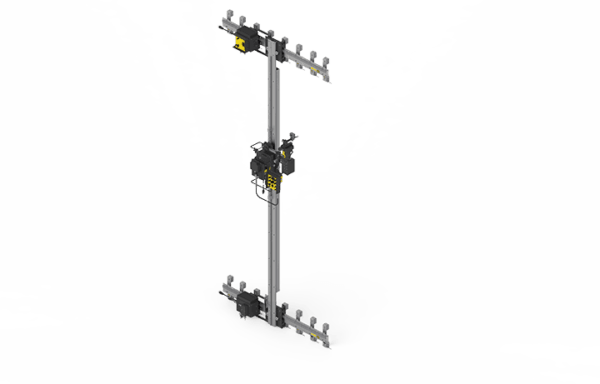

OVERLAY SYSTEM BUG-O

Easy Overlay Repair with Bug-O!

- Description

- Features

- Downloads

Description

The All Position Overlay System is designed for pulp digesters, boiler tube walls or any vessel or surface that requires overlay repair. The system will travel at a regulated, precise travel speed producing consistent uniform overlay patterns. A welding current sensor monitors and controls the welding torch height on pitted or irregular surfaces. The system can be customized for job specific applications on circumferences or flat walls and can be configured to handle a variety of operating windows. The entire system is portable and can be broken down into small pieces for moving thru small manholes or openings.

Features

- Customizable for job specific applications

- Portable system that can be taken to the work

- Pendulum weaver included along with welding torch height control

- Can be adapted for horizontal/step-up welding

- 2-20 ipm (50-508 mm/min) travel speed

- Full pendant control

- Cycle select module can be pre-set for continuous cycle, bi-directional stop at limit or rapid return at limit to start position

- Made in USA