MAXPRO200 plasma system Hypertherm

The MAXPRO200® LongLife® plasma cutting system is engineered for heavy-duty, high capacity automated and handheld cutting and gouging applications. The easy-to-use system operates with either air, oxygen, or nitrogen plasma gas, and combines fast cutting speeds and quick process changes to maximize productivity. Advanced Hypertherm consumable designs – including LongLife® technology – improve cut consistency and significantly increase consumable life to lower your cost per part.

- Benefits

- Specifications

- Operating data

- Resources

Benefits

Maximized productivity

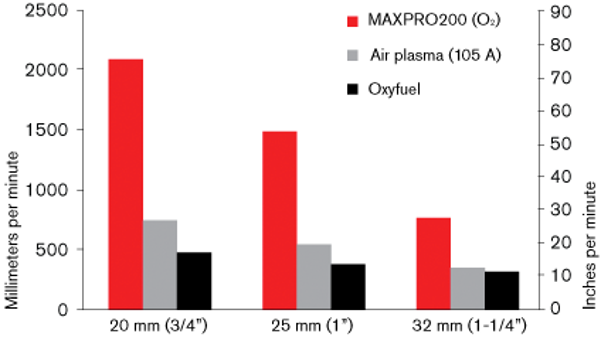

- Fastest cut speeds in its class produce more finished parts per hour

- Engineered with 100% duty cycle for the most demanding production environments.

- Automatic settings, tool free leads and optional quick disconnect torches let you quickly transition between cutting, gouging, mechanized and handheld processes

- Superior cut quality and consistency minimize the need for costly secondary operations

Fast cutting speeds = maximum productivity

Easy operation

- Optimized cutting parameters are automatically set and controlled in one step to deliver consistent results without operator intervention

- Advanced diagnostics simplify troubleshooting and service

- Optional serial communications allow full control of the system from the CNC

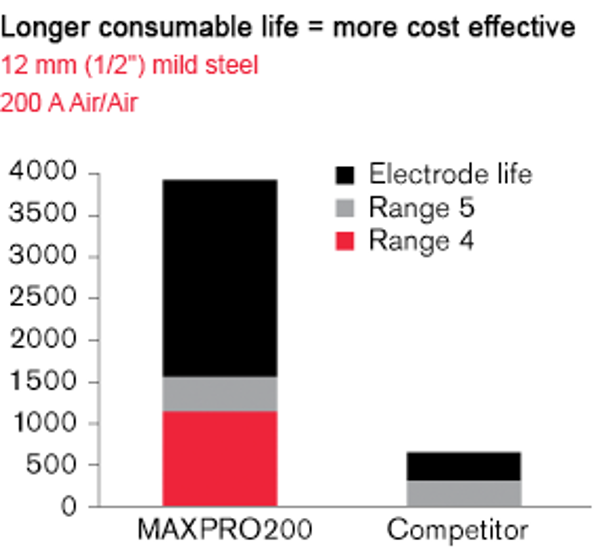

Low operating cost

- Patented consumable designs enable best in class cut speeds and robust production piercing using lower amperage levels

- Advanced consumable technologies including LongLife, CoolFlow™ and TrueFlow™ significantly increase consumable life to reduce cost per part

Industry-leading reliability

- Robust, simple system architecture with 50% fewer parts than most competitive systems

- Best-in-class manufacturing and extensive testing ensure that every Hypertherm system meets the highest quality standards

Specifications

| Input voltages | 200/208 VAC, 3-PH, 50 Hz, 108/104 A 220 VAC, 3-PH, 50 – 60 Hz, 98 A 240 VAC, 3-PH, 60 Hz, 90 A 380 VAC, 3-PH, 50 Hz, 57 A 400 VAC, CE, 3-PH, 50 – 60 Hz, 54 A 415 VAC, CE, 3-PH, 50 Hz, 52 A 440 VAC, 3-PH, 50 – 60 Hz, 49 A 480 VAC, 3-PH, 60 Hz, 45 A 600 VAC, 3-PH, 60 Hz, 36 A |

|---|---|

| Output voltage | 50 – 165 VDC |

| Maximum output current | 200 A |

| Duty cycle rating | 100% @ 33 kW, at 40° C (104° F) |

| Operating temperature | -10° C to 40° C (+14° F to +104° F) |

| Power factor | 0.98 @ 33 kW output |

| Maximum OCV | 360 VDC |

| Dimensions | 102 cm (40.14″) H, 69 cm (27.12″) W, 105 cm (41.23″) L |

| Weight | 335 kg (740 lbs) |

| Gas supply Plasma gas Shield gas Supply gas pressure | Air, O2, N2 Air, N2 6.2 +/- 0.7 bar (90 +/- 10 psig) |

Operating data

- Virtually dross-free cutting capacity – mild steel 20 mm (3/4″)

- Production pierce capacity – mild steel 32 mm (1 1/4″)

- Severance* – mild steel 75 mm (3″)

- Bevel – 200 amp consumables support 45° bevel capability

| Material | Current (amps) | Thickness (mm) | Approx. cutting speed (mm/min) | Thickness (inches) | Approx. cutting speed (ipm) |

|---|---|---|---|---|---|

| Mild steel Air plasmaAir shield | 50 | 13 | 80503760 | 20 ga0.135 | 340110 |

| Air plasma Air shield | 130 | 6 12 | 3865 2045 | 1/4 1/2 | 150 75 |

| Air plasma Air shield | 200 | 6 12 20 25 32 50 | 4885 2794 1415 940 630 215 | 1/4 1/2 3/4 1 1 1/4 2 | 190 110 60 35 25 8 |

| O2 plasma Air shield | 50 | 1 3 | 6775 3650 | 20 ga 0.135 | 270 130 |

| O2 plasma Air shield | 130 | 6 12 | 3925 2200 | 1/4 1/2 | 150 80 |

| O2 plasma Air shield | 200 | 6 12 20 25 32 50 | 6210 3415 1920 1430 805 270 | 1/4 1/2 3/4 1 1 1/4 2 | 235 130 80 55 32 10 |

| Stainless steelN2 plasma N2 shield | 200 | 1220 | 22601140 | 1/23/4 | 8050 |

| Air plasma Air shield | 200 | 12 20 | 3050 1520 | 1/2 3/4 | 120 60 |

| AluminumN2 plasma N2 shield | 200 | 1220 | 33701630 | 1/23/4 | 12570 |

| Air plasma Air shield | 200 | 12 20 | 3370 1625 | 1/2 3/4 | 125 70 |

*The thickness that can be severed at approximately 125 mm/min (5 ipm) with reduced cut quality. Cutting at severance thickness should be infrequent.