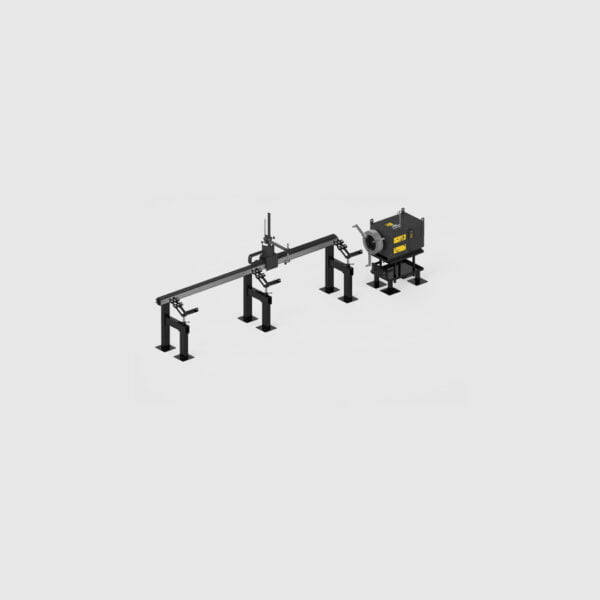

MM-5 BUG-O

Automated Heavy Duty Pipe Cutter Saves Layout and Fit-Up Time!

- Description

- Features

- Downloads

Description

The MM-5 is a computer-controlled machine that automates the cutting of profiles, holes, nozzles and shapes on pipe with diameters from 4″ to 39.375″ (10-100 cm). It features built in Auto Height Control for plasma cutting process. The MM-5 rotates the pipe on its roller bed with a three jaw chuck, while simultaneously moving a cutting torch back and forth along the pipe’s axis. Pre-programmed shapes such as saddle, hillside, lateral and miter cuts can be made by simply selecting the type of cut from the menu, then entering the diameters of the pipes and pressing the run button to cut your pipe. There is no need for templates, time consuming layout or calculations. In addition, irregular or custom shapes can be plotted, programmed and saved for future use.

Features

- Available for oxy-fuel or plasma cutting process in 120 and 240 volt models

- Built in automatic height control for plasma cutting process

- Cutting diameter of 4″ – 39.375″ (10-100 cm)

- Made in USA

- Eliminates the need for templates, layouts or calculations

- Pre-programmed shapes such as saddle, offset saddles, laterals, miter cuts, and holes can be made

- Irregular shapes can be plotted, pre-programmed and saved for future use